Vapour-based method for making crystals

An international team of scientists, led by KU Leuven in Belgium, has developed a method of producing crystals called metal-organic frameworks (MOFs) — said to be the world’s most porous materials — using vapour rather than liquid.

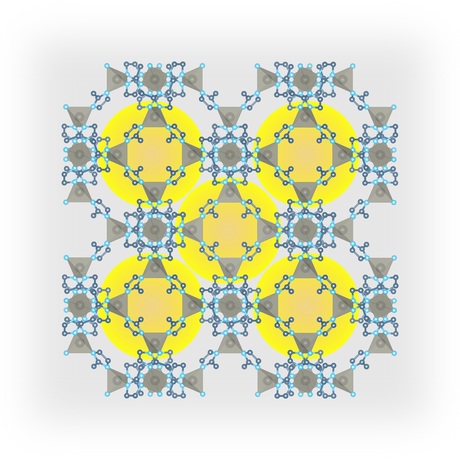

As explained by CSIRO researcher Dr Mark Styles, MOFs have the potential to significantly boost the processing power of microelectronic devices. They are like “bird cages that can be tailor made to be different shapes and sizes”, he said, featuring a regular pattern of tiny holes (nanopores) which contribute the crystal’s extremely large surface area.

“One gram of MOF crystals has a surface area of over 5000 m2 — that’s the size of a football field,” Dr Styles said.

“Crucially, we can use this vast space to trap other molecules, which can change the properties of a material.

“In the case of electronics, this means we can fit a lot more transistors on a microchip, making it faster and far more powerful.”

But up until now, these crystals could only be grown and applied using a liquid solvent, making them unsuitable for electronics applications. As explained by KU Leuven’s Professor Rob Ameloot, “The conventional method involves lab-scale wet chemistry — the traditional chemistry with solutions and solvents. The end result is a powder. For integrated, nanoscale applications, the particles of that powder are too large, while a method with solutions is not pure enough.”

Now, researchers have developed a vapour-based method of production that is analogous to steam hovering over a pot of hot water. The KU Leuven team, led by Professor Ameloot and his colleague Ivo Stassen, drew on specialist X-ray analysis techniques from CSIRO and the Australian Synchrotron to understand how the vapour process can be used to grow the MOF crystals.

“Vapour-phase deposition is already a common method to produce high-tech devices,” said Stassen, “[but] we are the first to use this method for the production of these highly porous materials. We first deposit layers of zinc and let them react with the vapour of the organic material. The organic material permeates the zinc, the volume of the whole expands and it is fully converted into a material with a regular structure and nanopores.”

It is believed that the alternative production method, published in the journal Nature Materials, opens up several new possibilities for MOFs in terms of applications and industries. Stassen explained, “Chemical vapour deposition is a common technique in nanofabrication; therefore, new MOF applications can be developed relatively quickly: gas sensors, nanochip components and improved batteries.”

DESI's 3D map more precisely measures the expanding universe

The Dark Energy Spectroscopic Instrument (DESI) has created the largest 3D map of our cosmos ever...

Toxic metal particles found in cannabis vapes

Nano-sized toxic metal particles may be present in cannabis vaping liquids even before the vaping...

Autonomous synthesis robot speeds up chemical discovery

Dubbed 'RoboChem', the benchtop device can outperform a human chemist in terms of speed...