GEA gets an in-house test lab

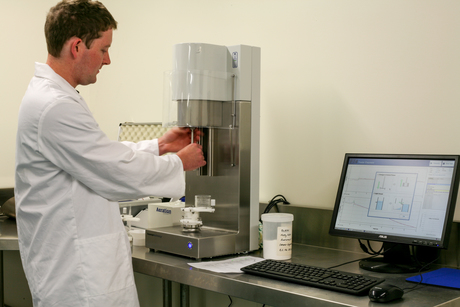

International technology group GEA has established its own in-house test laboratory at its facility in Hamilton, New Zealand.

GEA designs, manufactures and sells a wide range of powder filling systems for bulk bag and retail containers for use throughout the food and dairy industries. The new laboratory will enable the company’s engineers to carry out extensive tests on the properties of powders and to design powder packaging systems based on scientifically obtained data to optimise production and reduce waste.

Tests in the past have focused on characteristics such as particle size and density, but this did not enable engineers to predict how the powder would flow or how it would react to fluidisation and compaction on the production line. The new lab equipment measures seven vital characteristics of any given powder and enables engineers to design systems to suit each individual product.

“Until now, working out how any given powder would behave was something of a ‘black art’ or at least a ‘black science’, relying very much on experience and gut feel,” said GEA Engineering Manager Chris Singleton. “We have used outside labs in the past, but the turnaround was very slow and it was very expensive. Having our own lab means we can get accurate, quantifiable numbers quickly and relatively cheaply and use them in the design process.”

Having accurate information about the powders enables GEA’s engineers to advise customers on the design of factors such as the optimum wall angle of the filling hopper and the most suitable discharge diameter from vessels. The company will also size and shape vessels to ensure customers don’t have any problems with product transport or clogging during discharge.

The laboratory is also able to carry out the more traditional tests to classify powders for flowability, bulk density and particle size distribution. A vacuum filling test is also available to enable engineers to measure the accuracy that can be achieved when filling containers such as packs or cans with the customer’s product. The lab can test a wide range of powders, including those for infant formulas, coffee, muscle-building formulas, sports drinks and more.

Ultracold lab fridge modified for faster, more efficient cooling

By modifying a refrigerator commonly used in both research and industry, researchers have reduced...

Smartphone motion sensors used to detect heart failure

There is a non-invasive technique called gyrocardiography for measuring cardiac vibrations on the...

Fluorescent sensors 'light up' misfolded proteins in the brain

Researchers focused on developing a versatile fluorescent sensor array for amyloids to monitor...