A better way to create conductive polymers

A team led by La Trobe University scientists has found a new way to produce electricity-conducting materials known as a conductive polymers — and it could revolutionise smartphones and wearable technologies like medical devices. Their work has been described in the journal ACS Applied Materials & Interfaces.

Conductive polymers are synthetic materials which are widely used across all smart devices, from touchscreens on smartphones to medical devices that regulate a patient’s drug dosage and delivery. The new research disproves the longstanding belief that to create conductive polymers, substances like hyaluronic acid — well known due to its popularity in skincare — must be added to a mixture of water and polymer-forming particles.

The La Trobe technique instead uses hyaluronic acid applied directly to a gold-plated surface to create a thinner, more durable polymer, used to conduct electricity in devices like biosensors. In turns out that applying hyaluronic acid directly to the gold gives scientists total control over the material’s conductive properties, shape and appearance.

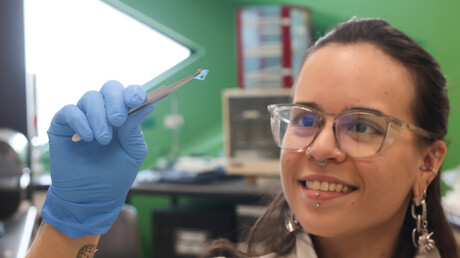

“We were very excited to find that not only did the polymers form when we tethered directly to the gold, but that these polymers were thinner, more powerfully conductive and almost foolproof to reproduce,” said lead researcher Luiza Aguiar do Nascimento, a PhD candidate at La Trobe.

The resulting material, called 2D PEDOT, is invisible to the naked eye and vastly more powerful than similar materials — attributes which give it the potential to have a huge impact on the future of smart, sensor-based devices. Lead researcher Associate Professor Wren Greene said the technique could thus lead to major improvements in the function, cost and useability of devices like touchscreens and wearable biosensors.

“Conductive polymers as we know them were developed nearly 50 years ago and although they’re exciting, they haven’t lived up to their potential in that time,” Greene said. “Often they are difficult to fabricate, as thin films don’t conduct electricity very well, aren’t transparent and can have highly variable properties.

“Through our method, called ‘tethered dopant templating’, we’ve created a robust way of making a conductive polymer that is flexible, durable, can conduct electricity as well as metals and is easily reproduced — so it’s scalable.”

Dr Saimon Moraes Silva, senior researcher and Director of La Trobe’s Biomedical and Environmental Sensor Technology (BEST) Research Centre, said the innovation could be particularly impactful in devices used in health and medical settings.

“Currently, it is difficult to consistently reproduce conductive polymers at the high quality needed for health and medical monitoring and drug delivery devices,” Moraes Silva said.

“I’m excited that we have created new capabilities for these materials which are scalable, affordable and reproducible.”

Microplastics found to alter the human gut microbiome

Microplastic-treated cultures showed a consistent and significant increase in acidity (lower pH...

Sustainable, self-repairing, antimicrobial polymers developed

From medicine to electronics and optics, new materials developed by scientists at Kaunas...

3D temperature mapping inside living tissue

Researchers have found a way to map temperature in three dimensions within biological tissue,...