Medieval glass-making technique kills hospital bacteria

UK scientists have discovered a technique similar to medieval stained glass-making that can completely eradicate the deadliest hospital infections within hours.

Using a so-called bioactive phosphate glass containing small amounts of the metallic element cobalt, researchers were able to achieve a ‘complete kill’ of the deadly bacterial infections Escherichia coli and Candida albicans (a fungal infection associated with surgery), as well as a near-complete kill of Staphylococcus aureus (the drug-resistant form of which is MRSA). Their work has been published in the journal ACS Biomaterials.

According to the European Centre for Disease Prevention and Control, over 4 million people in Europe get a healthcare-associated infection (HAI) every year, and around 37,000 die as a direct result of the infection. Seeking a way to combat this, researchers led by Aston University used a centuries-old technique to make glass laced with trace amounts of cobalt in a furnace heated to over 1000°C, before rapid cooling to prevent crystallisation. These were then ground down into a fine powder and put into contact with bacteria in petri dishes.

The glasses contained varying concentrations of cobalt, providing a controlled release of antimicrobial ions as they dissolved. At the highest concentration, the glass completely eradicated E. coli within just six hours, with a ‘complete kill’ also observed for C. albicans within 24 hours. S. aureus levels were reduced by 99% after 24 hours.

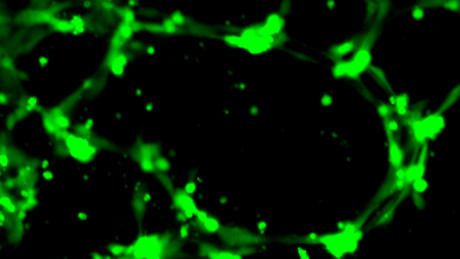

Bacteria that came into contact with the glass had their cell walls broken down by the metal ions, causing their contents to ‘leak out’. Ions also leached out from the glass, killing bacteria they were not in direct contact with.

Although bioactive glasses have been known about for some time, this is the first study to show that cobalt-doped bioactive glasses are effective in fighting specific bacterial microbes, opening the way for a wide range of cheap, antimicrobial implants and coatings to fight the most common sources of infections associated with medical care. This includes as biodegradable filling agents directly at the site of surgery, or drawn into fibres for soft tissue applications.

In fact, their most important use could be in catheters, which are needed by around 25% of hospital patients. Although sterile when inserted, when the collection bag is filled it is possible for bacteria to multiply and climb back up the catheter into the bladder, causing a urinary tract infection. To combat this, the researchers say it would be possible to insert a cartridge filled with antimicrobial glass in the line to stop the bacteria climbing back up the catheter into the patient.

“These glasses provide localised delivery at the surgical site to stop infections from forming in the first place,” said lead researcher Dr Richard Martin. “Once an infection has had time to establish itself it is much harder to treat, because complex bacterial biofilms start to form which are much tougher to tackle.”

It is also thought the bioactive glass could be effective against drug-resistant ‘superbugs’, helping to tackle the growing problem of antimicrobial resistance (AMR). Dr Martin explained, “These glasses have the potential to radically transform how we guard against common hospital infections, because if we can stop the bacteria from multiplying it negates the need for heavy doses of antibiotics.

“This would be good news for patients, who would be at a much-reduced risk of contracting a potentially life-threatening infection during a hospital stay, but also good for healthcare systems, which could make more judicious use of antibiotics and prevent costly unplanned hospital stays.”

Please follow us and share on Twitter and Facebook. You can also subscribe for FREE to our weekly newsletters and bimonthly magazine.

Proteomic approach identifies new blood-clotting disorder

Analysis of lethal antibodies has helped Australian and international researchers identify a new...

Blood test for chronic fatigue syndrome developed

The test addresses the need for a quick and reliable diagnostic for a complex,...

Droplet microfluidics for single-cell analysis

Discover how droplet microfluidics is revolutionising single-cell analysis and selection in...