Lightning used to make ammonia out of thin air

Researchers at The University of Sydney have harnessed human-made lightning to develop a more efficient method of generating ammonia — one of the world’s most important chemicals, and the main ingredient in the fertilisers that account for almost half of all global food production. Their research has been published in Angewandte Chemie International Edition.

Naturally occurring ammonia — mostly in the form of bird droppings — was once so high in demand it fuelled wars. The invention of the Haber–Bosch process in the 19th century made human-made ammonia possible and revolutionised modern agriculture and industry.

During the Haber–Bosch process, ammonia (NH3) is made by combining nitrogen (N2) and hydrogen (H2) gases under high temperatures and pressure in the presence of a catalyst (a substance that speeds up a chemical reaction). But the process comes at great climate cost, leaving a huge carbon footprint; it also needs to happen on a large scale and close to sources of cheap natural gas to make it cost-effective.

“Currently, generating ammonia requires centralised production and long-distance transportation of the product,” said Professor PJ Cullen from the University of Sydney’s School of Chemical and Biomolecular Engineering and Net Zero Institute, whose team has been working on ‘green ammonia’ production for six years.

Now, Cullen’s team has developed a more straightforward method to produce ammonia in gas form, which could bring us closer to the sustainable production of ammonia and the transition to a hydrogen-based economy (as ammonia contains three hydrogen molecules, it can be used as an effective carrier and source of hydrogen). Previous efforts by other laboratories have produced ammonia in a solution (ammonium, NH4+), which requires more energy and processes to transform it into the final gas product.

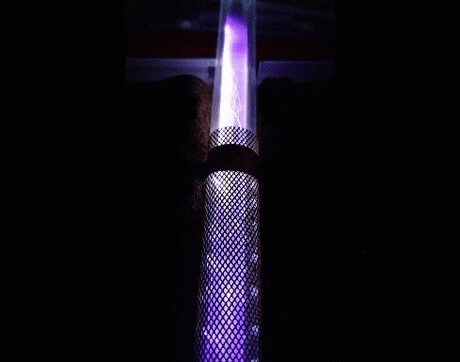

The new method to generate ammonia works by harnessing the power of plasma, by electrifying the air. The star of the process is a membrane-based electrolyser, a seemingly non-descript silver box, where the conversion to gaseous ammonia happens.

The plasma-based method Cullen’s team developed uses electricity to excite nitrogen and oxygen molecules in the air. The team then passes these excited molecules to the membrane-based electrolyser to convert the excited molecules to ammonia. The researchers said this two-step process, combining plasma and electrolysis, is a more straightforward pathway for ammonia production.

The team is now working on making the method more energy efficient and competitive compared to the Haber–Bosch process. According to Cullen, “We have already made the plasma component viable in terms of energy efficiency and scalability. To create a more complete solution to a sustainable ammonia productive, we need to push the energy efficiency of the electrolyser component.”

March workshops seek to empower NT flood evacuees

In March, a workshop series will bring together researchers and community members to co-design a...

Colon cancer DNA in blood can guide chemo decisions

A simple blood test could change how doctors decide which patients with colon cancer need...

Non-invasive blood test helps rule out oesophageal cancer

Designed and developed in Australia, the PromarkerEso test is designed to offer a quick,...