Cheap, compact spectroscopy with an infrared light filter

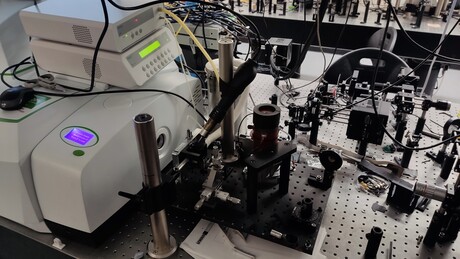

A heat-tuneable filter for infrared light, built on nanotechnology, promises handheld, robust technology to replace current desktop infrared spectroscopy set-ups that are bulky, heavy and cost anywhere from $10,000 to more than $100,000. The filter was developed at the ARC Centre of Excellence for Transformative Meta-Optical Systems (TMOS), and has been described in the journal Laser & Photonics Reviews.

Many materials can be easily identified from the way they absorb different parts of the infrared spectrum, so infrared spectroscopy is useful for monitoring for contaminants, for example in industrial processes. Spectroscopy relies on spreading the light source into a spectrum, which is conventionally done with a grating or prism to spread the infrared light: different parts of the spectrum are sent into the sample by tilting the grating back and forth.

The TMOS team instead opted for a non-moving component to select specific parts of the infrared spectrum, in the form of a bandpass filter. Drawing on other research within TMOS that had used heating to vary component behaviour, they devised a filter with temperature-dependent bandpass wavelength. This is made possible by making the filter from silicon, whose refractive index shifts smoothly with temperature.

“The great thing about it is that it is very stable and reversible,” said Ben Russell, a PhD student at TMOS and The University of Melbourne.

To generate bandpass behaviour from the silicon, the team used a metasurface — a layer of silicon approximately 1.5 µm thick with an array of nanoscale features carved into it, sitting on a layer of sapphire (Al2O3) 470 µm thick. Initially Russell modelled the dimensions of the metasurface, coming up with two possible solutions: parallel grooves or crossed grooves. While the parallel grooves gave better spectral properties, they were sensitive to the polarisation of the light, whereas the two-dimensional, crossed pattern was not.

Russell created prototypes of both options by carefully etching the pattern into an off-the-shelf silicon-on-sapphire wafer. Sure enough, the finished prototype behaved as modelled, displaying a linear wavelength shift of 80 nm across the standard operating temperatures from 25 to 420°C. More extreme heating and cooling to cryogenic temperatures extended this to 140 nm (although these extremes are unlikely to be of practical use in the future).

With stable temperature tuning achieved, the team tested the spectroscopic capabilities of the filter on a number of everyday items, for example successfully measuring polymide tape and a zinc selenide window. They were also pleased to be able to easily distinguish between two clear, recyclable plastics of different composition, LDPE and PET.

Because the new technology is built on silicon technology, its manufacture can be scaled, with the potential to push costs down below $1 per filter. This makes it ideal for use in mid-infrared systems, said TMOS Deputy Director Professor Kenneth Crozier.

“There are high-performance systems available, but they are expensive,” Crozier said. “This smaller, lighter, low-power technology could open up a lot of applications, for example field testing of agricultural products, such as milk and olive oil, and screening and sorting of recycled materials.”

A non-destructive way to locate microplastics in body tissue

Currently available analytical methods either destroy tissue in the body or do not allow...

Rapid imaging method shows how medicine moves beneath the skin

Researchers have developed a rapid imaging technique that allows them to visualise, within...

Fluorescent molecules glow in water, enhancing cell imaging

Researchers have developed a new family of fluorescent molecules that glow in a surprising way,...