Tiny optical device brings atoms to a standstill

Scientists at the US National Institute of Standards and Technology (NIST) have miniaturised the optical components required to cool atoms down to a few thousandths of a degree Celsius above absolute zero — the first step in employing them on microchips to drive a new generation of super-accurate atomic clocks, enable navigation without GPS and simulate quantum systems. Their work has been published in the New Journal of Physics.

Cooling atoms is equivalent to slowing them down, which makes them a lot easier to study. At room temperature, atoms whiz through the air at nearly the speed of sound — around 343 m/s — which means they have only fleeting interactions with other particles, and their motion can make it difficult to measure transitions between atomic energy levels. When atoms slow to a speed of 0.1 m/s, researchers can measure the particles’ energy transitions and other quantum properties accurately enough to use as reference standards in a myriad of navigation and other devices.

For more than two decades, scientists have cooled atoms by bombarding them with laser light, a feat for which NIST physicist Bill Phillips shared the 1997 Nobel Prize in Physics. Although laser light would ordinarily energise atoms, causing them to move faster, if the frequency and other properties of the light are chosen carefully, the opposite happens. Upon striking the atoms, the laser photons reduce the atoms’ momentum until they are moving slowly enough to be trapped by a magnetic field.

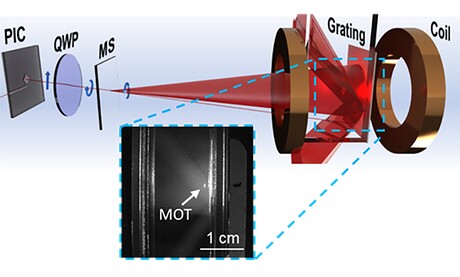

But to prepare the laser light so that it has the properties to cool atoms typically requires an optical assembly as big as a dining room table, which limits the use of these ultracold atoms outside the laboratory. Now NIST researcher William McGehee and his colleagues have devised a compact optical platform, only about 15 cm long, which cools and traps gaseous atoms in a 1 cm-wide region. Although other miniature cooling systems have been built before, this is said to be the first that relies solely on flat, or planar, optics, which are easy to mass produce.

The apparatus consists of three optical elements. First, light is launched from an optical integrated circuit using a device called an extreme mode converter. The converter enlarges the narrow laser beam, initially about 500 nm in diameter, to 280 times that width. The enlarged beam then strikes a carefully engineered, ultrathin film known as a ‘metasurface’ that’s studded with tiny pillars, about 600 nm in length and 100 nm wide. The nanopillars act to further widen the laser beam by another factor of 100, which is necessary for the beam to efficiently interact with and cool a large collection of atoms. Moreover, by accomplishing that feat within a small region of space, the metasurface miniaturises the cooling process.

The metasurface reshapes the light in two other important ways, simultaneously altering the intensity and polarisation (direction of vibration) of the light waves. Ordinarily, the intensity follows a bell-shaped curve, in which the light is brightest at the centre of the beam, with a gradual falloff on either side. The NIST researchers designed the nanopillars so that the tiny structures modify the intensity, creating a beam that has a uniform brightness across its entire width. The uniform brightness allows more efficient use of the available light. Polarisation of the light is also critical for laser cooling.

The expanding, reshaped beam then strikes a diffraction grating that splits the single beam into three pairs of equal and oppositely directed beams. Combined with an applied magnetic field, the four beams, pushing on the atoms in opposing directions, serve to trap the cooled atoms.

Each component of the optical system — the converter, the metasurface and the grating — was developed at NIST but in operation at separate laboratories across the two NIST campuses. McGehee and his team brought the disparate components together to build the new system.

“That’s the fun part of this story,” McGehee said. “I knew all the NIST scientists who had independently worked on these different components, and I realised the elements could be put together to create a miniaturised laser cooling system.”

Although the optical system will have to be 10 times smaller in order to laser-cool atoms on a chip, the experiment “is proof of principle that it can be done”, McGehee said. It thus serves as a key step towards employing ultracold atoms in a host of compact, chip-based navigation and quantum devices outside of a laboratory setting.

“Ultimately, making the light preparation smaller and less complicated will enable laser-cooling-based technologies to exist outside of laboratories,” McGehee said.

Please follow us and share on Twitter and Facebook. You can also subscribe for FREE to our weekly newsletters and bimonthly magazine.

Liquid handling with machine learning — the perfect screening combo?

In December, scientists at St. Jude Children's Research Hospital made public a screening...

Best practices for safe centrifugation in the laboratory

The majority of all centrifuge accidents are understood to result from user error. These tips...

Nature-inspired filtration system recovers critical resources

A filtration system that can recover untapped critical resources such as copper and lithium from...