Enhancing liquid measurement precision with Coriolis sensor-based mass flow meters and controllers

Precise liquid measurement, regulation and dispensing are essential in a range of industries, including pharmaceuticals and biotechnology processes, and in food processing and chemical processes for precise dosing. It is also important in other manufacturing processes such as thin-film coating, and in the production of fuel cells, electrolysers and batteries.

In many of these applications high precision is required at very low flow rates. In these cases, mass flow meters and controllers based on the Coriolis principle have a number of advantages.

The Coriolis measurement principle

The Coriolis measurement principle involves an excitation coil setting a measurement tube into high-frequency oscillation. When a liquid flows through the oscillating tube, the Coriolis force acts upon the liquid, leading to a phase shift — the difference in tube oscillation between its start and end. Sensors measure the phase shift, which is directly proportional to the mass flow rate.

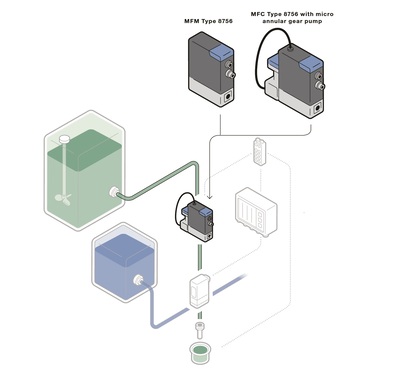

The Burkert Type 8756 Mass Flow Meters and Mass Flow Controllers (MFM/MFC), based on the Coriolis principle, are particularly suitable for the very precise measurement or control of small quantities of liquid that also require a medium-separated sensor.

The Type 8756: both a flow meter and a controller

The heart of the Type 8756 is its Coriolis sensor — featuring a slender measurement tube with a diameter of DN1 — which forms the basis for a range of configurations, including mass flow meters (MFM) and mass flow controllers (MFC).

Available in two sizes (Size 1 for up to 25 kg/h flow rate and Size 2 for up to 120 kg/h), the Type 8756 can be a flowmeter, or a controller available in a number of variants:

- With an interface for a modular actuator that is suitable for applications up to 100 bar pressure.

- With an integrated proportional valve.

- With an integrated high-precision micro-annular gear pump that is self-priming and hermetically sealed.

The variant with an integrated pump is used as a control or dosing system for liquids that have to be conveyed from an unpressurised container.

The sophisticated design of the Type 8756, coupled with a high excitation frequency, renders the device highly resilient to external vibrations, and since it lacks moving parts within the medium, has high durability. It can accommodate fluids with high density and viscosities of up to 200 mPa-s and can be calibrated using water, regardless of the application.

Because of the Coriolis principle, pressure and temperature deviations have no impact on the measuring accuracy. In addition to the flow rate, the density and temperature of the liquid are also measured. The device design enables a stable flow measurement that is immune to external impacts and does not require a zero-point adjustment when the process conditions change. All materials that come into contact with the medium are highly resistant and enable use with a variety of liquids, whether aggressive or neutral media.

Integrated batch control

In addition to continuous flow measurement and regulation, the Type 8756 offers a variant with integrated batch control capabilities. Precision is paramount in dispensing and filling applications, where even minor variations can lead to quality issues. With the integrated batch controller, this device ensures consistent dosing regardless of temperature or pressure fluctuations, offering a dosing accuracy of approximately 0.3% of the measured value. Every dosing event is documented, enabling efficient monitoring and reproducibility of the process.

The Type 8756 Coriolis MFM/MFC with its robust Coriolis sensor is a game-changer in liquid measurement and control. Its adaptability, precision, and durability make it an indispensable tool in a wide array of industries, ensuring consistent and reliable performance in challenging environments. Whether the application is in pharmaceuticals, food production, or chemical processing, the Type 8756 offers a reliable solution for any liquid measurement need.

For more information, please visit www.burkert.com.au/en/type/8756.

Burkert Microsensors: Precision and Partnership for Critical Laboratory and Medical Applications

Burkert microsensors are engineered for seamless integration into laboratory and medical devices,...

Safeguarding Cryopreservation: When Failure Is Not an Option

Vaisala's viewLinc Continuous Monitoring System was developed with high-stakes applications...

World First — Clever Engineering and Flexible Technology Solves a Nanoparticle Challenge

It is not every day that you get to solve a unique problem. But that's exactly what happened...