Safeguarding Cryopreservation: When Failure Is Not an Option

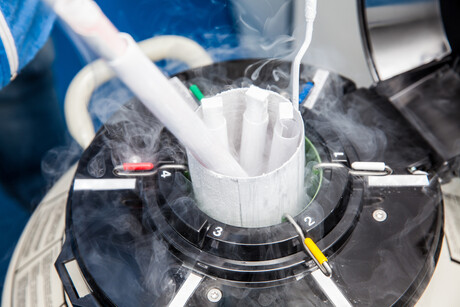

Failures in cryogenic tank monitoring can have devastating consequences — particularly in fertility and biobanking facilities where irreplaceable human tissues are stored. In several high-profile cases, thousands of reproductive tissues were lost when remote alarms failed to notify personnel of tank issues.

Many customers have chosen the viewLinc Continuous Monitoring system after their LN2 tank alarm had been inadvertently disabled by personnel. Had viewLinc been monitoring, an alert would have been sent to designated personal that an alarm was disabled. Incidents like this underscore the critical need for robust monitoring systems designed not only to detect risk, but to prevent alarm disablement and ensure alerts reach personnel immediately.

Secure Monitoring Solutions for LN2 Applications

Vaisala’s viewLinc Continuous Monitoring System was developed with high-stakes applications in mind. Used globally in regulated GxP environments, viewLinc provides secure, real-time monitoring with a focus on reliability and accountability.

Cryogenic storage can be monitored using Vaisala’s RFL100 wireless data logger or the VDL200 data logger with TMP115 probe — both designed to measure extreme low temperatures down to -196°C for LN2 tank applications.

Key system safeguards include:

- Secure remote alarming via email, SMS, and voice calls — 24/7 alerts regardless of time or personnel location

- User-specific permissions and an audit trail that records every system interaction

- Multi-stage alarm settings

- Simplified system validation with IQOQ documentation

- Timed alarm pauses for maintenance, with automatic reactivation after the set period

Built for High-Stakes LN2 Monitoring

In viewLinc, alarms are never truly “off” — they’re carefully controlled, logged, and subject to review. If someone disables or acknowledges an alarm, the audit trail shows who did it, when, and what comments were added. viewLinc supports multiple alarm escalation paths and configurable alarm thresholds, including high/low, communication loss, and open circuit conditions. Alarm messages include live sensor values and can repeat at designated intervals until resolved. Real-time access is available via PC, smartphone, or wall-mounted monitors, giving users a clear overview of conditions at all times.

Protecting Biobanks, Reproductive Materials, and Cellular Therapies

When the stakes are this high, “good enough” isn’t good enough. viewLinc was built with the understanding that human error is inevitable — but preventable system failures are not. Whether for reproductive tissues, cell therapies, or biological samples, the viewLinc system helps protect what matters most — ensuring that critical materials remain safely stored and continuously monitored. Failure is not an option — and with viewLinc, it doesn’t have to be.

FAQ on monitoring LN2 Applications

1. How does viewLinc send alarms?

viewLinc Enterprise Server sends alarms by email, SMS/text, phone (dial out), local light/siren (alarm enunciator), or via PC monitor. Multi-stage alarming is also available.

2. How do sensor probes and probe wires hold up at Liquid Nitrogen temperatures?

The TMP115 temperature probe is a platinum RTD temperature sensor that provides outstanding measurement. The linearity and excellent long-term stability make platinum RTD probes ideal for most LN2 applications. The RFL100 wireless data logger or Ethernet based VDL200 data logger are both compatible with TMP115.

3. How accurate are the temperature readings?

The accuracy of the sensor will depend on the device and the device you use will depend on your application needs and network connectivity preferences. The TMP115 comes with a traceable calibration certificate and measurement performance from -196°C to -90°C.

4. Does Vaisala require someone from their company to perform onsite validation annually?

Vaisala does not require a Vaisala employee to visit your site(s) annually. However, we offer on-site validation, installation, and calibration services. Alternately, you can perform your own annual testing and/or calibrations. We also offer factory calibrations at several centers globally. Some customers keep spare probes on-hand for out-of-tolerance readings, but this happens rarely.

5. Can you add or remove an input (data logger) yourself?

Yes. viewLinc Enterprise Server users can make changes such as adding or removing inputs/loggers. Vaisala’s technical support is there to assist you by web conference if needed.

6. Can a user acknowledge alarms remotely?

Yes, you can acknowledge alarms remotely. The system also captures all actions performed by individual users in viewLinc’s secure audit trail.

7. What reports are available?

viewLinc provides reports on historical measurement data, alarm conditions, and system configuration.

- Automated reporting — Customized Reporting can be set up to email PDF reports automatically to users at defined intervals (daily/weekly/etc.).

- On demand reporting — Users can create reports on the fly for historical data or real-time trending. All viewLinc reports are customizable with user-defined criteria such as every sample, min/max/avg., alarms with corrective action.

8. What are the power requirements of data loggers?

RFL100 data loggers are powered by two standard AA size 1.5 V batteries (LR6 alkaline or FR6 lithium) for 18 months of operation at approximately 20°C. When fresh batteries are inserted during yearly calibration, battery replacement between calibrations is not needed.

VDL200 is powered by PoE (Power over Ethernet) with a battery backup. VDL200 uses commonly available AA size 1.5 V alkaline (LR6) and lithium (FR6) batteries.

9. How do you view data during the business day and after business hours?

viewLinc ES data can be accessed via PC/Laptop/Smart phone. Simply open a browser and login to viewLinc to see real-time values and trending, acknowledge alarms, and other actions.

10. What other types of environments can viewLinc monitor?

- Temperature

- Humidity

- CO2

- Differential Pressure

- Door contact or alarm contact outputs

- Other measurements like particulate (via analog inputs, Modbus devices)

Enhancing precision and control in modern cell culture workflows

The accuracy, precision and speed of liquid handling are fundamental to experimental success in...

Pendotech's innovative single-use sensors now available in Australia and New Zealand

The availability of Pendotech products in Australia and New Zealand signals a major advancement...

Burkert Microsensors: Precision and Partnership for Critical Laboratory and Medical Applications

Burkert microsensors are engineered for seamless integration into laboratory and medical devices,...